The Odlewnia Kowala company was established in 1986 by Erwin Kowala. Nowadays, the company is managed by the second and third generation. We manufacture aluminium casts. Our operations are located in Ustroń and Chybie in the Silesia Voivodship. In the first one, which also is our headquarters, we manufacture casts in sand casting technology. The latter is dedicated to die cast technology products. From the begging, the cast sales systematically grow and currently are at the level of approximately 450 tons per year.

DEVELOPMENT OBJECTIVES

In our development, we aim at offering wide range of casts made using our own production capabilities, becoming independent from external companies. This will allow us to become even more competitive. Purchase of the CNC AVIAturn 50M lathe in 2016 was one of the first steps to achieve our goals.

EXPORT OBJECTIVE

A significant increase of export, especially in terms of sand casting products is one of our latest successes. We supply our products for companies operating in Germany, Czech Republic, Slovakia, the Netherlands, Denmark, Great Britain, Lithuania, France, Sweden.

We are seeing a huge potential in terms of exporting aluminum casts to EU countries and therefore our goal is to regularly increase its share in total sales.

SPONSORING

In 2015 and 2016 we sponsored the ULTER SPORT Really Team in the Opel Adam Cup: Jerzy Tomaszczyk and Łukasz Sitek.

BUSINESS VALUES

As a family-run company, in our management we follow the principles of honesty, responsibility and tradition which are indispensable for building a company stable for generations.

Thanks to our cooperation with Family-Run Businesses Foundation we us a Family-Run Business tree.

A Multigenerational Company with Tradition and a Modern Approach to Quality

Our company is a multi-generational business with traditions. We have been present on the market for over 30 years now. We draw on the experience of our founders and we combine it with the achievements of modern technology. We have been operating according to the principles of the ISO 9001 Quality Management System for 15 years now. We invest in our staff, our equipment, and the development of our employees’ competence, because we know it translates into high standards of the services we offer. Thanks to our own capacities, as well as our cooperation with external businesses, we offer comprehensive services: from a mould to a fully processed casting.

Our company has been honoured with the prestigious title of a “Business Gazelle”, awarded to the most dynamically developing small and medium enterprises.

New headquarters in Chybie

We constantly receive new contracts from our satisfied customers, as well as we win new ones, which translates into a constant increase of sales.

We are an independent company with a well-equipped machine park. All castings are made on our premises from scratch. We make every effort to make sure our workmanship is immaculate and our prices are attractive. We develop, analyse, and customise every single project. In doing so we are guided by precision. We pay attention to accuracy when working on every single detail, and at the same time we make sure that the end product satisfies the standards in force in Poland and abroad.

We manufacture our castings exclusively from top-quality attested raw materials, which are delivered by our reliable suppliers. We make use of casting moulds and models created in cooperation with our trusted contractors. We monitor subsequent stages of the production process and we improve our Quality Management System. Thanks to that, we are certain that our product is 100% compliant with the plans, free from any defects, reliable, as well as optimised so as to meet the customer’s expectations.

Precision Manufacturing and Quality That Builds Trust

In our aluminium foundry we make castings to be used in the machine industry, electrotechnical industry, power engineering, automotive industry, construction, agriculture. We produce castings in small and large batches.

We systematically increase the export share in the total sales. Currently, we deliver our products to companies operating in 6 European states.

We guarantee professional services based on comprehensive solutions, a flexible approach to customers’ needs, expert advice, and all this at competitive prices!

Our Company is divided into two plants. The branch in Ustroń manufactures sand castings, whereas the branch in Chybie specialises in pressure castings and CNC machining.

History

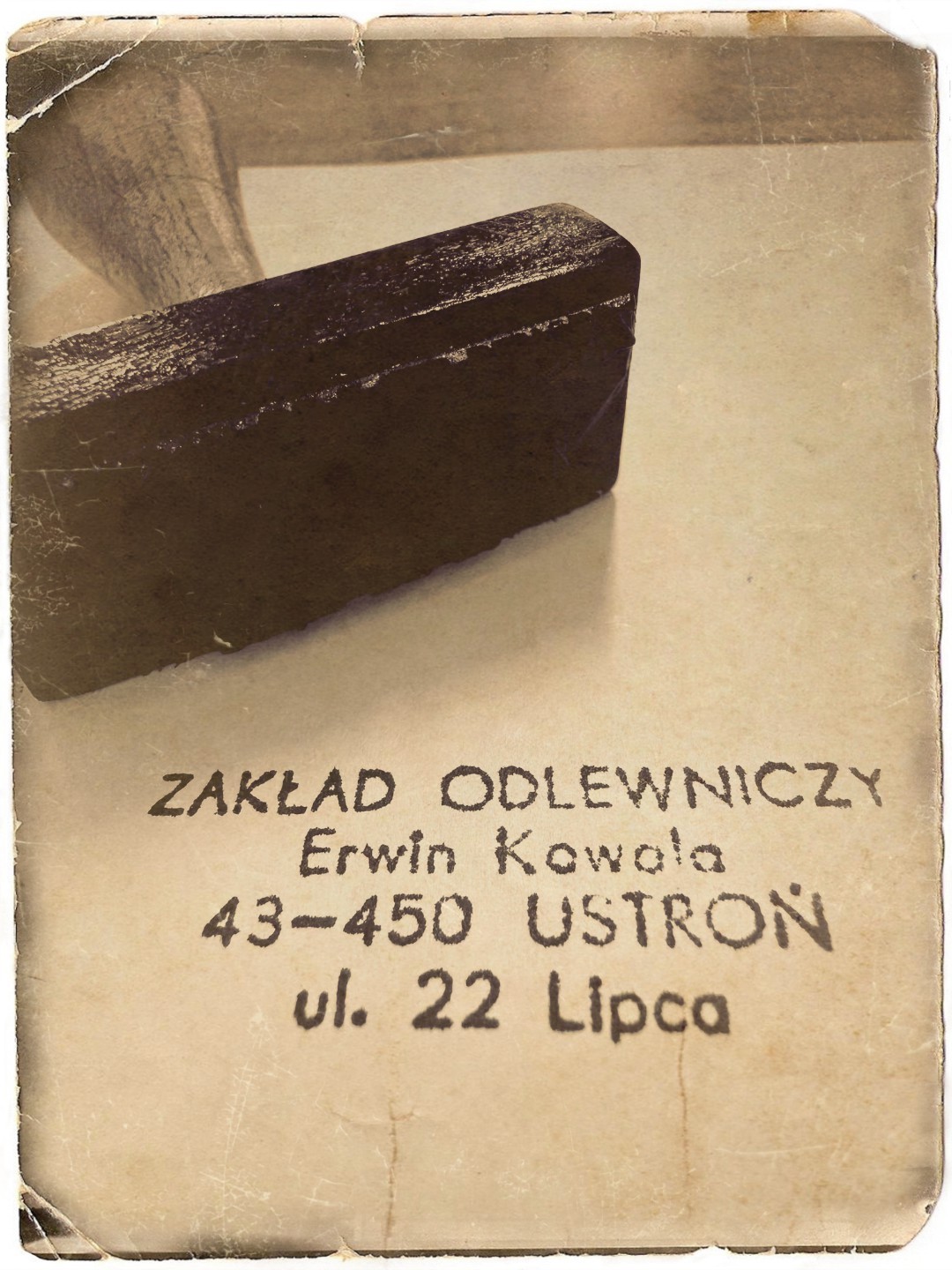

ODLEWNIA KOWALA was founded in 1986 by Erwin Kowala. Initially, the facility was located exclusively at Daszyńskiego 70a in Ustroń, formerly known as 22 Lipca Street. When starting his journey in casting, Erwin focused on sand casting.

In 1998, Adam Kowala purchased a plot in Chybie to open a second production hall, where we now perform die casting.

After 37 years, the company is managed by the second and third generations.

Interesting Facts

Odlewnia Kowala has been part of exceptional projects that made their mark on the history of Polish cinema. One notable project was the creation of cannon barrels for the film "With Fire and Sword" (Ogniem i mieczem, 1999). These authentic, brass cannon barrels, each weighing 220 kg, were specially crafted in our foundry for this production. Working on such a casting was a significant challenge, requiring precision and expertise – brass reaches a temperature of 1,000°C, making the process both technically and logistically demanding.

The entire casting process was described by Jacek Drost in an article for Dziennik Bielski in 1998, where he detailed each stage of the project. This event not only highlights our high technical standards but also serves as an example of how Polish casting craftsmanship supported the film industry by providing realistic props for one of the most important productions in Polish cinema.

We export our castings to:

The First Company Stamp